Versatile drilling rig concept

The drilling rig can be used in a range of ways, for example for micropiles and mini piles, GEWI piles, for underpinnings, jet grouting work and uplift anchors.

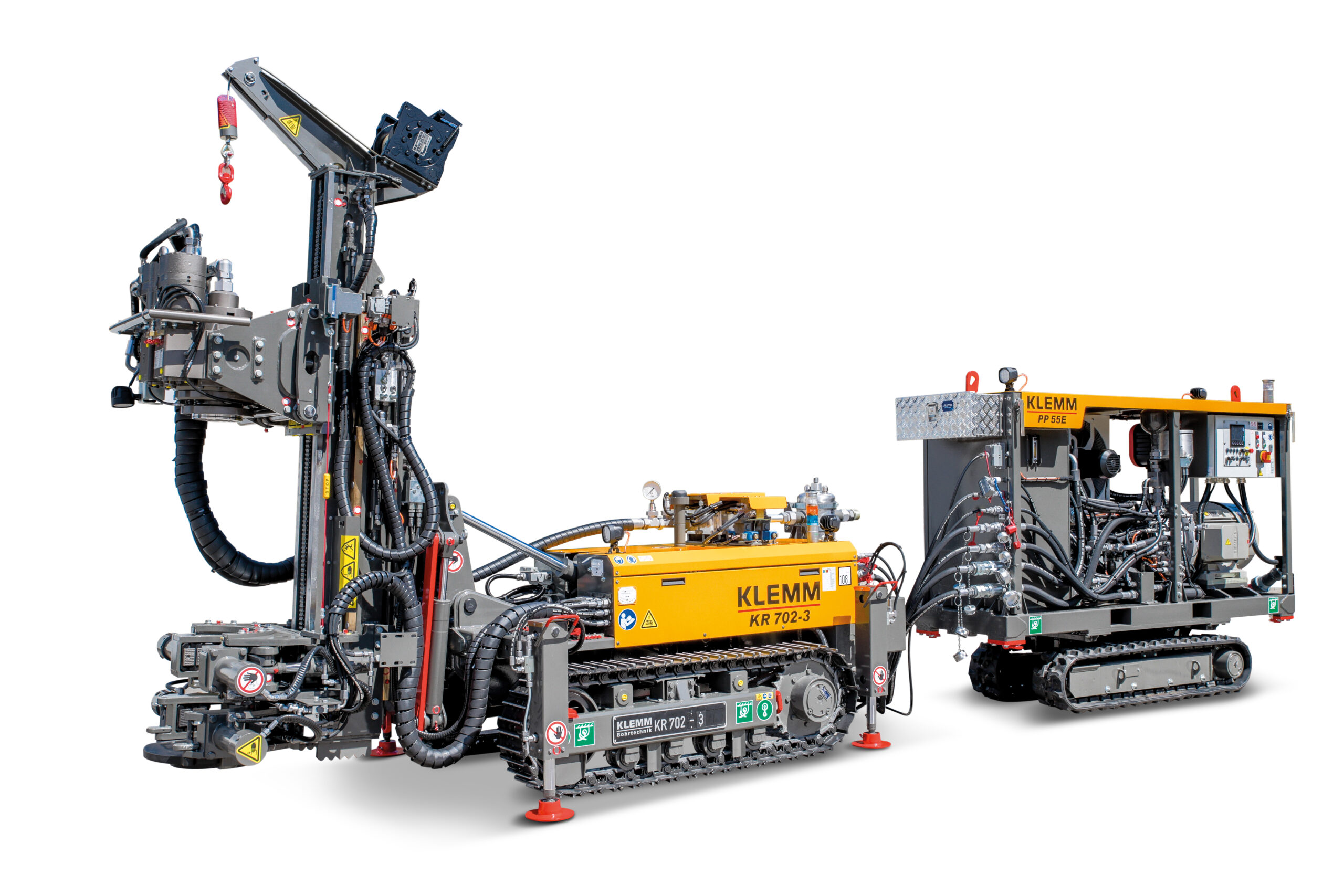

Working in tight spaces

The KR 702-3 drilling rig is especially suited to work in confined spaces. For extremely compact dimensions, special attention was paid to the optimum design of the rig in terms of performance capability, load-bearing capacity and versatility. The KR 702-3 can be used in confined spaces, as it fits through doors which are up to 2400 mm high and 750 mm wide.

Because the crawler undercarriage can be projected to 1250 mm and has two-point support as standard, it provides excellent stability in all drilling situations. Each side of the crawler undercarriage and each support can be moved separately.

Operator Safety

With the tried and tested radio remote control with display, the operator can take up a safe working position around the drilling rig at all times. In accordance with the requirements of EN 16228, operator safety is ensured by the high functional safety of the control concept. An interlocking movable guard for moving parts in the drilling process is available.

High Performance

The drive of the external Power Pack (129 kW) is extremely efficient in relation to its compact size. The Power Pack complies with the EU Emission Standard Tier 5 for mobile drilling rigs. In combination of the PP 117G with the KR 702-3, the EEP (Energy-Efficient Power) and power-sharing technologies are on board.

Electric alternative

With the PP 55E, it is possible to work without exhaust emissions and with reduced noise. The power-sharing technology and the two main pump circuits enable automatic and optimised power distribution according to actual demand.

Fagerstagatan 51

163 53 SPÅNGA